The Importance of Temperature Sensors in Industrial Settings

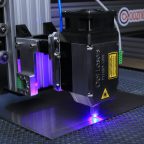

Temperature sensors are pivotal in maintaining optimal operations across various industrial settings. From manufacturing plants to energy facilities, these devices play a crucial role in ensuring efficiency, safety, and product quality.

This blog explores who needs temperature sensors and why they are indispensable in industrial environments.

Who Needs Temperature Sensors?

1. Manufacturing Plants

Manufacturers rely on temperature sensors to control and monitor processes that involve heat, such as in the production of metals, plastics, and chemicals. Accurate temperature readings are essential to ensure that materials are processed at the correct temperatures, which affects both the quality and consistency of the final product.

For example, in the automotive industry, temperature sensors monitor the curing process of composite materials to guarantee structural integrity. For detailed information and solutions regarding temperature sensors and other process control technologies, visit https://www.processparameters.co.uk/.

2. The Food and Beverage Industry

In the food and drinks industry, temperature sensors are crucial for maintaining proper storage conditions and ensuring product safety. These sensors help monitor temperatures in refrigeration units, cooking processes, and during transportation.

For instance, sensors ensure that food is cooked to the correct temperature to kill harmful bacteria and that refrigerated items are kept at safe temperatures to prevent spoilage.

3. The Energy Sector

Energy production and distribution facilities use temperature sensors to monitor and control various components of their systems, including turbines, generators, and pipelines. In power plants, sensors track the temperature of steam and cooling systems to optimize performance and prevent overheating. In oil and gas operations, temperature sensors help detect anomalies that could indicate potential safety hazards or equipment failures.

4. The Pharmaceutical Industry

Pharmaceutical manufacturers use temperature sensors to ensure that their products are produced and stored under precise conditions. This is vital for the stability and efficacy of medicines. Sensors monitor temperatures in storage areas and during the production process to comply with regulatory standards and maintain the quality of medications.

Why Are Temperature Sensors Needed?

1. To Ensure Product Quality

Temperature sensors ensure that industrial processes are carried out within specified temperature ranges, which is crucial for maintaining product quality. Variations in temperature can lead to defects, inconsistencies, or substandard products. By providing real-time temperature data, sensors help operators make necessary adjustments and maintain the integrity of the production process.

2. To Enhance Safety

Temperature sensors are vital for safety in industrial settings. Overheating equipment or processes can lead to dangerous situations, including fires or explosions. Sensors provide early warnings of temperature anomalies, allowing for timely intervention to prevent accidents. In industries involving energy and chemicals, where high temperatures are common, temperature sensors are essential for maintaining safe operational conditions.

3. To Improve Efficiency

By monitoring temperatures closely, industrial operations can optimize their processes for better efficiency. For example, in heating, ventilation, and air conditioning (HVAC) systems, sensors help regulate temperatures to ensure that energy is used efficiently, therefore reducing waste and operational costs. In manufacturing, sensors can help in maintaining precise control over production conditions, leading to more efficient use of resources and reduced downtime.

4. To Ensure Regulatory Compliance

Many industries are subject to strict regulatory standards that require precise temperature control. Temperature sensors help companies comply with these regulations by providing accurate and reliable data. In industries like food and pharmaceuticals, where regulations are stringent, maintaining proper temperature control is not only important for quality but also for legal compliance.

Conclusion

Temperature sensors are an integral part of modern industrial operations, impacting various sectors from manufacturing to energy production.

As technology advances, temperature sensors will continue to evolve, offering even more precise and reliable monitoring capabilities for industrial settings.