How Automation and Robots Are Transforming the Automotive Industry

The recent developments in Industry 4.0, such as robotics and automated machinery, are now everywhere. Indeed, the latest generation of automated industrial equipment can handle several aspects of production, from assembly to repairs. Here’s how robotics and cutting-edge heavy machinery are reshaping this industry.

Crafted to Perfection

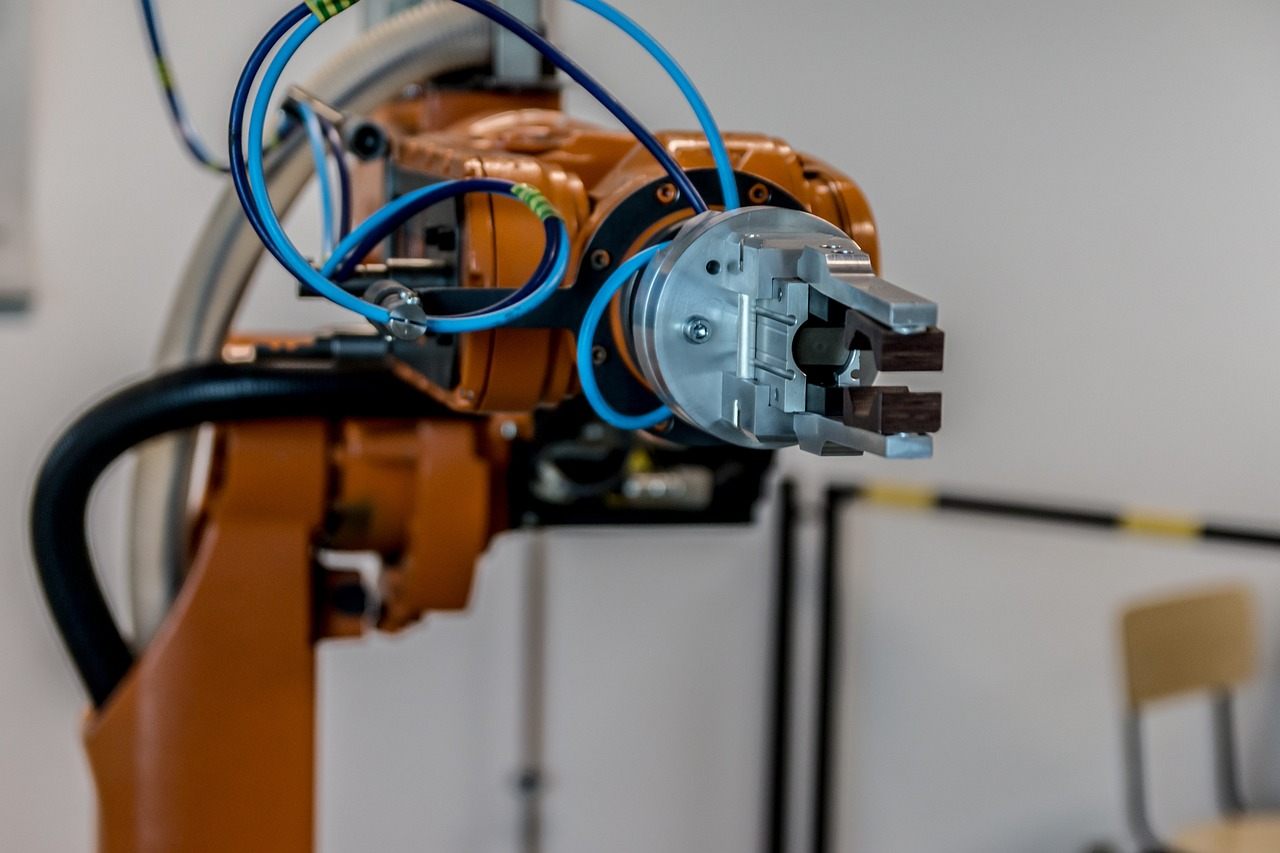

Robots have been on the production line in factories since the 1960s. The first model, Unimate, handled tasks like welding and die-casting. Since the 1980s, automotive manufacturers have implemented more automated machinery, thanks to artificial intelligence (AI) advancements and the Internet of Things (IoT).

Indeed, industrial automation has become a massive market, projected to cross the USD 218 billion mark in 2027. Companies like topautomazioni provide cutting-edge technology for industrial robots, including arms, rolling machines, and automated machines for loading/unloading components, all necessary on the factory floor of automotive brands.

Here are some benefits of robotic automation for the automotive market:

Cost-Effectiveness

New technologies, like AI-controlled sensors, can cut costs and increase production capacity. These sensors identify defects in real-time, reduce machine downtime, and reduce maintenance costs. Sensor-equipped machinery can also adjust production according to the demand, resulting in fewer rejected parts.

Improved Quality

Automated assembly provides greater quality control in the production line, improving accuracy and ROI. Moreover, automated assembly ensures consistent quality standards across the line.

More Safety for Workers

Robots automate the more physical tasks, lowering the risk of accidents. A fully automated production line cuts physical exertion or human errors to zero. Additionally, real-time monitoring systems can provide quick responses to accidents.

The Future of Automation

The automotive industry is highly competitive, and manufacturers must always be ahead of the corner to reach their market goals. That’s why they’re quick to implement new technologies in their production line, speeding up assembly, reducing material waste, and cutting costs. Here’s what the future looks like.

Data-Driven Production

Data science has improved significantly in the past few years. Collecting, storing, and analysing huge amounts of data is possible, providing insightful information about production efficiency, predicting issues and market trends, and suggesting innovative solutions.

Physical Tasks

Robots for the automation of physical tasks will gain more space, covering even more aspects of the production line. We can also expect to see more refined robots, like the “seeing” robot introduced by Ford, that can singlehandedly install fenders, windshields, doors, and other body parts with zero defects.

Intelligent Ecosystem

We’re not too far from intelligent automation of the entire industry, with chatbots taking orders from customers and redirecting them to the nearest dealership to collect their orders. The vehicle’s system will be able to seamlessly integrate with your home's mobile devices and even smart features.

Conclusion

Undoubtedly, the automotive market is attuned to Industry 4.0's innovation. Intelligent machinery and systems are already a reality on the factory floor, paving the way to zero-defect quality standards at every step of the production process. The companies that built such equipment constantly update their systems and technologies, providing more efficient solutions at every turn.